Architectural Pulls:

- Quality, aesthetically pleasing door pulls often used in commercial building entrances

- Various designs, materials, and finishes to match the architectural style of the building

- Frequently found in high-traffic applications

Push Bars:

- Horizontal bars mounted across the door, allowing users to push the door open

- Simple design, often made of metal, and can be used as a safety feature

- Common in commercial buildings, emergency exits, and high-traffic areas

Decorative Pulls:

Description: Door pulls designed with an emphasis on aesthetics and style

Features: Available in various artistic designs, materials, and finishes to complement interior decor

Usage: Used in residential and commercial spaces to enhance the visual appeal of doors

Long Door Pulls:

- Extended length pulls that run vertically along the door

- Provide a modern and sleek look, making them easy to grasp from different heights

- Popular in contemporary commercial and residential buildings, especially on large doors

Hands-Free Door Pulls:

- Designed to allow users to open doors without using their hands, typically using their forearm or foot

- Promotes hygiene and reduces the spread of germs

- Ideal for health care facilities, public restrooms, and any high-traffic area where hygiene is a concern

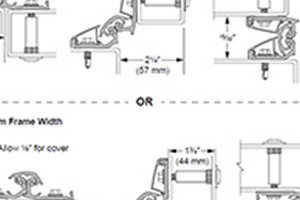

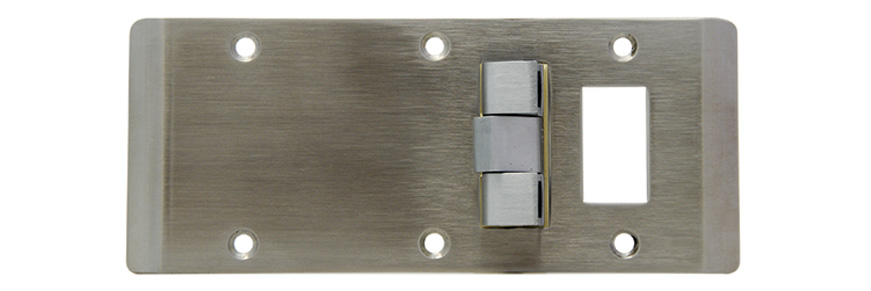

Push and Pull Plates:

- Flat plates installed on doors to facilitate opening and closing by pushing or pulling

- Common in high-traffic areas such as restrooms, secondary doors, and public buildings

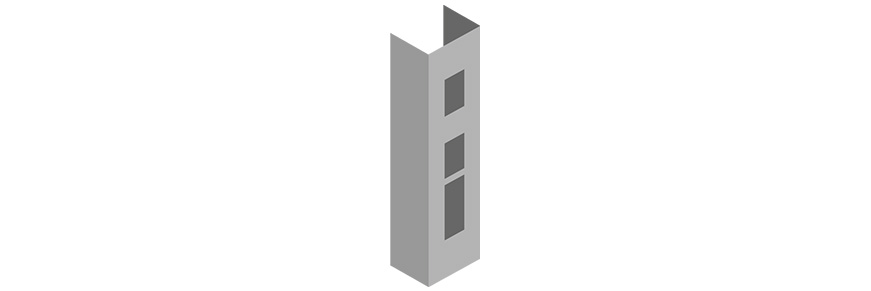

Vandal Resistant Trim:

- Door hardware designed to withstand tampering and vandalism

- Robust construction, often with reinforced materials and tamper-proof fasteners

- Suitable for public buildings, schools, and other areas prone to vandalism

Flush Pulls:

- Recessed pulls that sit flush with the surface of the door

- Minimalist design, providing a sleek and unobtrusive look

- Commonly used on sliding doors, pocket doors, and cabinets

Sliding Door Pulls:

- Handles specifically designed for sliding doors

- Often recessed or surface-mounted, allowing for smooth operation of the sliding mechanism

- Used on closet doors, patio doors, and room dividers

Each type of door pull serves a specific function and aesthetic, catering to different needs and environments. Choosing the right type depends on the door's purpose, the desired look, and the level of durability required.

-871x291.jpg)

%20-871x291.jpg)