- Architectural Hinges

- Brackets, Hooks & Sockets

- Door Stops, Holders & Silencers

- Edge Guards & Vandal Resistant Trim

- Exterior Hardware

- Flush Pulls & Sliding Door Pulls

- Flush Bolts, Strikes & Coordinators

- Geared Continuous Hinges

- Latches, Catches & Bolts

- Pin & Barrel Continuous Hinges

- Pivots

- Pulls, Push Bars & Plates

- Rescue Hardware

- Window Hardware

-

Products

Architectural Hinges

Discover Ives architectural hinges for residential and commercial use, including full mortise, swing clear, wide throw, and electrified options.

Brackets, Hooks & Sockets

Complete your spaces with Ives brackets, hooks, and sockets, offering stylish and durable solutions for handrails, coats, hats, and wardrobe organization.

Door Stops, Holders & Silencers

Protect walls and doors with Ives stops, holders, and silencers, offering durable solutions for noise reduction, door management, and damage prevention.

Edge Guards & Vandal Resistant Trim

Protect high-traffic doors with Ives edge guards and vandal-resistant trim, featuring durable stainless steel designs for schools and public buildings.

Exterior Hardware

Explore Ives exterior hardware, including lock guards, viewers, knockers, and mail slots, designed for durability, security, and weather resistance.

Flush Pulls & Sliding Door Pulls

Enhance sliding and pocket doors with Ives flush pulls and sliding door pulls, available in decorative and standard designs for any application.

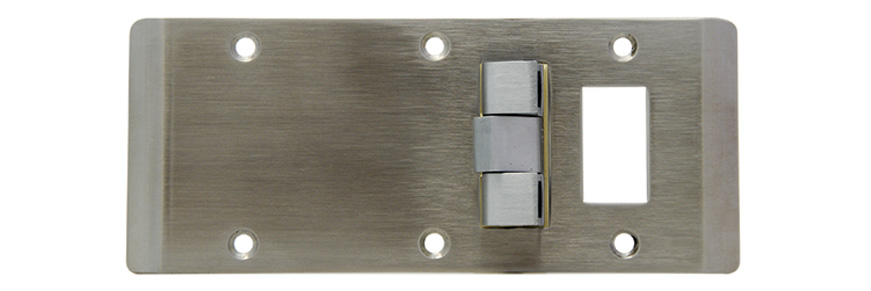

Flush Bolts, Strikes & Coordinators

Secure double doors with Ives flush bolts, dust-proof strikes, and coordinators, designed for durability, proper sequencing, and fire safety compliance.

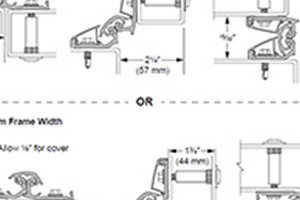

Geared Continuous Hinges

Discover Ives geared continuous hinges with options like XY and HD models for lasting durability, weight distribution, and seamless door operation.

Latches, Catches & Bolts

Keep doors closed with Ives latches, catches, and bolts, offering solutions for secure latching, door guards, and additional security enhancements.

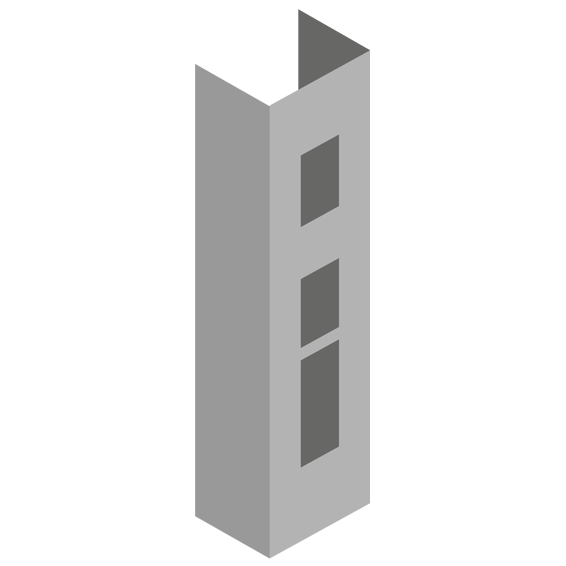

Pin & Barrel Continuous Hinges

Explore Ives pin & barrel continuous hinges, including stainless and primed steel options, for enhanced security, durability, and seamless performance.

Pivots

Reduce stress on frames with Ives pivots, including offset, center hung, and power transfer options, designed for durability and smooth operation.

Pulls, Push Bars & Plates

Ives door pulls, push bars, and plates, including architectural, decorative, and hands-free options, for durable and versatile door solutions.

Rescue Hardware

Ensure quick access in emergencies with Ives rescue hardware, allowing bi-directional door swings for hospitals and nursing homes.

Window Hardware

Explore Ives window hardware, including lifts, locks, casement fasteners, and adjusters, designed to secure windows and complement any style. -

Solutions

By Market

Find the right solutions for your K-12, higher education, health care, multifamily, government and commercial real estate projects.-871x291.jpg)

By Role

Explore Ives resources tailored for architects, facility managers, general contractors, locksmiths, and distributors to meet hardware needs efficiently.%20-871x291.jpg)

By Requirement

Find Ives solutions for fire-rated doors, accessibility, healthy buildings, quiet environments, BAA compliance, and electrified hardware needs. - Resources

- Why Ives